BLT Series

Balanced & container –type shaft seal with all the parts assembled

together no axial rotating to prevent the shaft and rubber parts from

wearing, with the characteristics of rapid changing ,easy installation

and safe operation. Dynamic sealing is made of cemented carbide

materials and static sealing is fluorine rubber material which makes

the mechanical seal to be high temperature resistance long service

life, easy changing and other significant characteristics.

The built-in floating sealing ring of the pump cavity body could

minimize the internal leakage produced by the differebtial pressure

and prevent the energy consumption when liquid leaking back to the

pump cavity body.

Cold extrusion spline shaft with good surface quality, high machining

accuracy, at the same time improve the comprehensive mechanical

properties of the shaft and the reliability of the pumb.

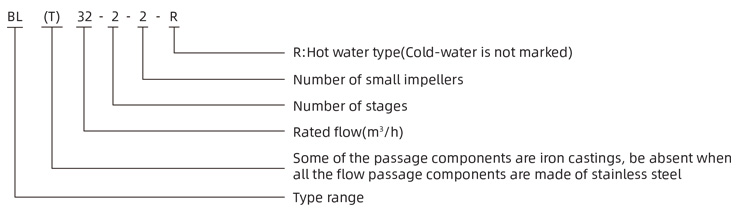

Model Instruction

Overview Of The Product

BL(T) series stainless steel multi-stage centrifugal pump (afterwards called pump)boasts characters of high efficiency, low noise, steady operation, etc.The pump set adopts the non-self-priming vertical multi-stage structure, which makes a compact whole,its installation easy, its operation and maintenance convenient.

Application Limits

- Medium temperature: normal type: 0 °C ~ 68 °C hot water type: 0 °C ~ 120 °C,

- Ambient temperature: +40 °C ,

- Max ambient pressure: 1.0MPa,

- Advisable to use motor of higher power in case that the density or viscosity of medium is above that of water.

- pH: 5 to 8

| Water supply | BL | BLT |

|---|---|---|

| Filtration and transfer at waterworks | • | • |

| Distribution from waterworks | • | • |

| Pressureboosting in mains | • | • |

| Pressure boosting in high-rise buildins,hotels,etc. | • | • |

| Pressure boosting for industrial water supply | • | • |

| Industry | ||

| Pressure boosting | • | • |

| Process water systems | • | • |

| Washing and cleaning systems | • | • |

| Vehicle washing tunnels | • | • |

| Fire fighting systems | • | • |

| Liquid transfer | ||

| Cooling and air-conditioning systems(refrigerants) | • | • |

| Boiler feed and condensate systems | • | • |

| Machine tools(cooling lubricants) | • | • |

| Aquafarming | • | • |

| Transfer | ||

| Oil and alcohol | • | • |

| Glycol and coolants | • | • |

| Water treatment | ||

| Ultra-filtration systems | • | • |

| Reverse osmosis systems | • | • |

| Softening, ionising, demineralizing systems | • | • |

| Distillation systems | • | • |

| Separators | • | • |

| Swimming baths | • | • |

| lrrigation | ||

| Field irrigation(flooding) | • | • |

| Sprinkler irrigation | • | • |

| Drip-feed irrigation | • | • |

Certificate

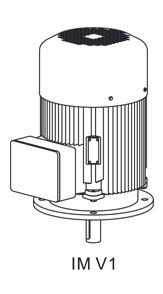

Electric Motor

- Full-enclosed and ventilating two-pole standard motor

- Protection class: IP55

- Insulation class: F

- Standard voltage Single phase 220V-50Hz Three phase: 220/380V - 50Hz

Energy Efficiency Standard (IEC60034)

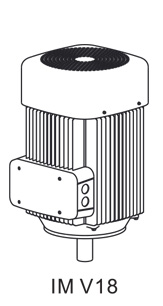

| Standard Specific | ||||

|---|---|---|---|---|

| Power(kW) | Efficiency (2P, IE2) | Efficiency (2P,IE3) | Motor Structure | |

| 0.75 | 77.4 | 80.7 | IMV18 |  |

| 1.1 | 79.6 | 82.7 | ||

| 1.5 | 81.3 | 84.2 | ||

| 2.2 | 83.2 | 85.9 | ||

| 3 | 84.6 | 87.1 | ||

| 4 | 85.8 | 88.1 | ||

| 5.5 | 87 | 89.2 | ||

| 7.5 | 88.1 | 90.1 | ||

| 11 | 89.4 | 91.2 | IMV18 |  |

| 15 | 90.3 | 91.9 | ||

| 18.5 | 90.9 | 92.4 | ||

| 22 | 91.3 | 92.7 | ||

| 30 | 92 | 93.3 | ||

| 37 | 92.5 | 93.7 | ||

| 45 | 92.9 | 94 | ||

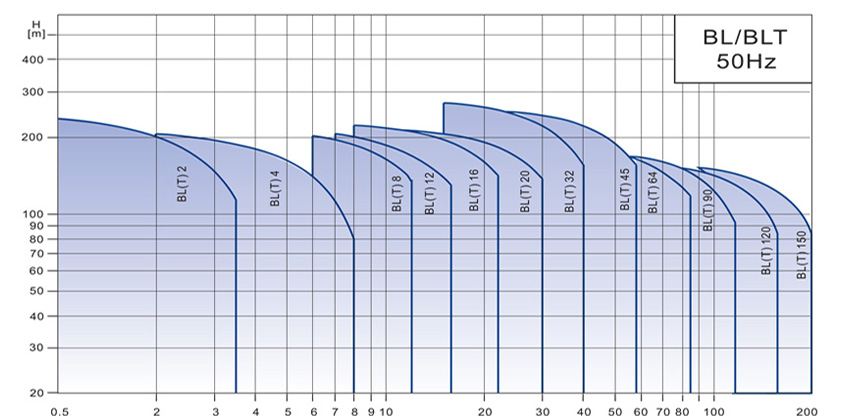

Performance Range

| Model | BL(T)2 | BL(T)4 | BL(T)8 | BL(T)12 | BL(T)16 | BL(T)20 | BL(T)32 | BL(T)45 | BL(T)64 | BL(T)90 | BL(T)120 | BL(T)150 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rated Flow (m3/h) | 2 | 4 | 8 | 12 | 16 | 20 | 32 | 45 | 64 | 90 | 120 | 150 |

| Flow Range (m3/h) | 1 - 3.5 | 1 - 5.7 | 5 - 11 | 7 - 16 | 8 - 20 | 14 - 28 | 16-40 | 25-55 | 30-80 | 50-110 | 60 - 150 | 80 - 180 |

| Max.Pressure (bar) | 23 | 21 | 21 | 22 | 22 | 23 | 27 | 28 | 22 | 16 | 17 | 16 |

| Motor Power (kW) | 0.37-3 | 0.37-4 | 0.75-7.5 | 1.5-11 | 2.2-15 | 2.2-18.5 | 3-30 | 5.5-45 | 7.5-45 | 11-45 | 11-75 | 11-75 |

| Max. Efficiency (%) | 45 | 57 | 62 | 63 | 66 | 67 | 70 | 74 | 75 | 76 | 75 | 76 |

| DIN Flange | DN25 | DN32 | DN40 | DN50 | DN50 | DN50 | DN65 | DN80 | DN100 | DN100 | DN125 | DN125 |

| Pipe Thread | R 211/4 | R 211/4 | Rc2,on request | |||||||||

| Oval flange | G1orG11/4 | |||||||||||

| Tamperature Range | Standard Type 0 - +68 °c Hot Water Type 0 - +120 °c | |||||||||||

Performance Curve - BL(T)2

2.jpg)

Performance Table

| Model | Power | Caliber | Q (m3/h) |

1.5 | 2 | 3 | 4 | 5 | 6 | 7 | Head Range kW HP (m) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW | HP | |||||||||||

| BL(T)2-2 | 0.37 | 0.5 | 32mm (11/4') |

H(m) | 18 | 17 | 16 | 15 | 13 | 12 | 10 | 10 - 19 |

| BL(T)2-3 | 0.37 | 0.5 | 27 | 26 | 24 | 22 | 20 | 18 | 15 | 15 - 27 | ||

| BL(T)2-4 | 0.55 | 0.75 | 36 | 35 | 33 | 30 | 26 | 24 | 20 | 20 - 36 | ||

| BL(T)2-5 | 0.55 | 0.75 | 45 | 43 | 40 | 37 | 33 | 30 | 24 | 24 - 45 | ||

| BL(T)2-6 | 0.75 | 1 | 53 | 52 | 50 | 45 | 40 | 36 | 30 | 30 - 53 | ||

| BL(T)2-7 | 0.75 | 1 | 63 | 61 | 57 | 52 | 47 | 41 | 35 | 35 - 63 | ||

| BL(T)2-9 | 1.1 | 1.5 | 80 | 78 | 73 | 67 | 61 | 54 | 45 | 45 - 80 | ||

| BL(T)2-11 | 1.1 | 1.5 | 98 | 95 | 89 | 82 | 73 | 64 | 54 | 54 - 98 | ||

| BL(T)2-13 | 1.5 | 2 | 116 | 114 | 106 | 98 | 89 | 78 | 65 | 65 - 116 | ||

| BL(T)2-15 | 1.5 | 2 | 134 | 130 | 123 | 112 | 100 | 90 | 73 | 73 - 134 | ||

| BL(T)2-18 | 2.2 | 3 | 161 | 157 | 148 | 136 | 121 | 108 | 91 | 91 - 161 | ||

| BL(T)2-22 | 2.2 | 3 | 197 | 192 | 180 | 165 | 148 | 130 | 110 | 110 - 197 | ||

| BL(T)2-26 | 3 | 4 | 232 | 228 | 214 | 198 | 178 | 158 | 130 | 130 - 232 | ||

Performance Table

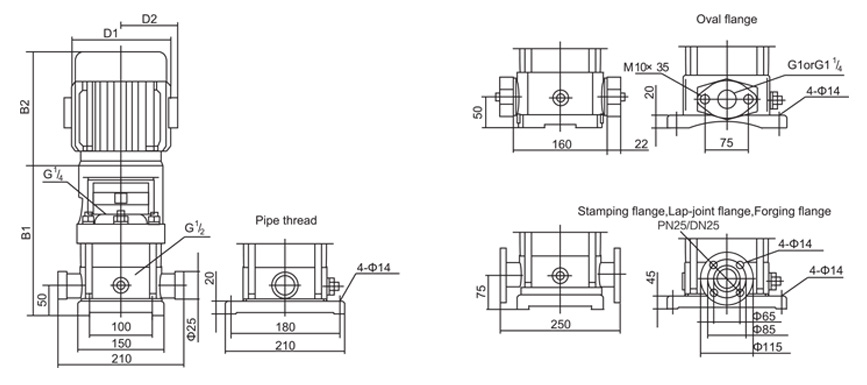

| Model | Dim.(mm) | N.W.(kg) | |||||

|---|---|---|---|---|---|---|---|

| B1 | B2 | B1+B2 | D1 | D2 | BL | BLT | |

| BL(T)2-2 | 278 | 220 | 498 | 135 | 86 | 21 | 26 |

| BL(T)2-3 | 278 | 220 | 498 | 135 | 86 | 21 | 26 |

| BL(T)2-4 | 296 | 220 | 516 | 135 | 86 | 23 | 28 |

| BL(T)2-5 | 314 | 220 | 534 | 135 | 86 | 23 | 28 |

| BL(T)2-6 | 340 | 255 | 595 | 148 | 96 | 27 | 31 |

| BL(T)2-7 | 358 | 255 | 613 | 148 | 96 | 27 | 32 |

| BL(T)2-9 | 394 | 255 | 649 | 1148 | 96 | 30 | 34 |

| BL(T)2-11 | 430 | 255 | 685 | 1148 | 96 | 31 | 35 |

| BL(T)2-13 | 479 | 300 | 779 | 166 | 115 | 34 | 39 |

| BL(T)2-15 | 515 | 300 | 815 | 166 | 115 | 35 | 40 |

| BL(T)2-18 | 569 | 300 | 869 | 166 | 115 | 39 | 44 |

| BL(T)2-22 | 641 | 300 | 941 | 166 | 115 | 41 | 46 |

| BL(T)2-26 | 722 | 325 | 1047 | 191 | 128 | 49 | 54 |

High-efficiency standard motor, Japan NSK bearings and cold-rolled

50ww800 silicon steel sheet made the pump high efficiency, low noise

and mainenance-free. Totally enclosed shaft steel, IP55 protection

grade, F class insulation grade, the special "double-lock" drive and

bearing made the pump withstand higher inlet pressure.

Being produced by the most advance international laser welding

technology no eliminate welding, ensure the high intensity and

efficiency . The processing technology precision casting .CNC lathe,

CNC machining center , the modern advanced technology such as the

laser welding technique and processing equipment.

The pump core parts are designed to be multilevel interlocking,

fastening nut locked, components system interlock assembly industry

to minimize the gap between the impeller per level, improve the

efficiency of the impeller water conservancy, and ensure the stability,

reliability and efficiency of the pump core components.