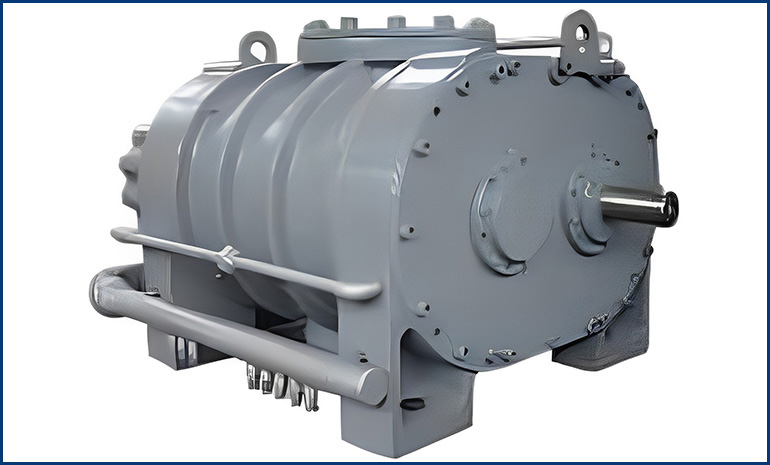

Water Cooled Seriess

Water Cooled Series (Water Cooled)

Products Range :

- Suction Capacity from 10 M3/Hr to 5000 M3/Hr.

- Pressure Upto 1.0 Bar

- Vacuum upto 0.50 Bar

Product Design

AMIKON Roots Type Rotary Blowers are Heavy-duty Units designed with Integral Profile. The Head Plates, Gear Cover, Drive , Cover & rigid, One Piece Casting of Gray iron. Carburized and Ground alloy Steel helical timing gear and mounted on the shafts, secured with tensioning Element Spherical Roller & Deep Groove Ball Bearing are Used.

All Components are Machined to very accurate dimensions with extremely tight tolerance with guaranteed interchange ability. The Casting of casing and main covers are stress relived after are Pre-machining for dimensional stability at elevated temperature. Both sides of the side cover are oil filled which increases the life of bearing and Gears.

The Twin-lobe Impeller Profile Ensures Maximum Volumetric efficiency with Minimum Power absorption. All Units come equipped with rugged steel mounting feet to permit in field adaptability to either vertical or horizontal installation requirements.

All AMIKON blowers Unit may Operate under either Vacuum or Pressure Application with no equipment modification. All UGRK Series are available with Special seals for gas applications.

Special Features

- Machines are air cooled so water-cooling in not required

- Positive Displacement Machines with content Volume Characteristic.

- 100% Oil Free Compression

- Suitable for various Gases such as Air, Town Gas, Natural Gas, Nitrogen, Hydrogen, Carbon dioxide, inert gases.

- Effective Sealing Ensured By Means of Temperature-insensitive labyrinth system.

- High Precision chemical timing gears for reliability and long life.

- Overhung V-Belt drive for all operating pressure ranges. Direct coupling also possible

- Dynamically balanced rotating components to ensure vibration free operation.

- Machine shaft height matched with standard IEC Motor Frame size.

- Solid, noise-absorbing construction in grey cast iron.

Working Principle

Water-Cooled Air Blowers are similar to air-cooled type blowers in construction and performance-except for the addition of a cooling arrangement.

In water-cooled blowers, the main casing and side plates have water jackets around them. Through which water is circulated, which dissipates the heat generated and keeps the internals cool. Water-cooled blowers are recommended for applications where discharge pressures exceed 10-psi (or 7000-mm WG).

n applications where the differential pressure is in excess of 10-psig, it is both essential and recommended to dissipate the heat for efficient working and longevity of the blower bearings and seals. These blowers have a unique design of single inlet and single outlet for cooling water and no cumbersome water pipe connections externally. Internal circulation of water to various areas is achieved through in-built channels. This unique design makes the operations very simple, yet very effective. The cooling water inlet is at the bottom so that the water rises up against gravity, reaching all the corners before it comes out from the outlet. The flow rate of cooling water required are low.